Green Terminal

| Number of Berth |

4 berths |

| Terminal Length |

1,500 meters (375 meters for each) |

| Terminal Width |

475 meters |

| Area |

74.8 hectares |

| Depth |

-16.5 meters |

Gate Operation

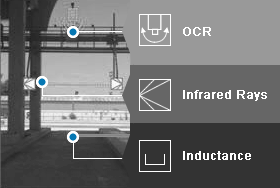

OCR

OCR - Optical Character Recognition

OCR

OCR - Optical Character Recognition

- Tractor plate no. auto-recogniton

- Container no. auto-recognition

Infrared Rays

- Identify if there is container loaded on chassis

Inductance

- Underground

- Recognize 20' or 40' chassis

KIOSK

KIOSK

- No need to get off tractor

- Check and auto-release

- Location slip auto-print

- Fast pass

- Manual gate for back up

Advantage

Advantage

- Accelerate the passing time to gate to 1~1.5 minutes

- Reduce idle time, reduce fuel consumption by 36,270 liters per year, which is equivalent to a saving of carbon dioxide emissions by 100,830 kg every year.

CY Operation

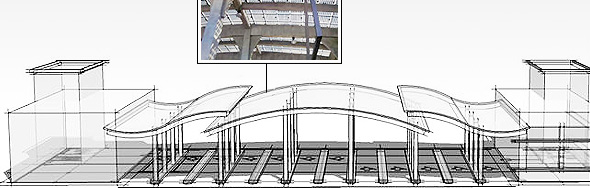

ARMG- Automated Rail Mounted Gantry Cranes

ARMG- Automated Rail Mounted Gantry Cranes

- Gauge : 42.5M (14 rows under span)

- Tier : 5 stacking tiers + 1 passing tier

- Loading Capacity : 40T

- Manpower saving

- Safety

- Saving of carbon dioxide emissions by 4,487,190kg every year

Remote Control Station

Remote Control Station

- CCTV on ARMGs

- Each operator handles 4~6 ARMGs

- Auto shifting in slack time

One-Man Bridge Navigation System

One-Man Bridge Navigation System

- ARMGs are actived by RFID

- Info. is shown on LED screen

Advantage

- Accelerate the passing time to gate to 13~11 minutes

- Reduce idle time, reduce fuel consumption by 72,540 liters per year, which is equivalent to a saving of carbon dioxide emissions by 201,661 kg every year.

Shipside Operation

GC (Tandem Lift Cranes)

GC (Tandem Lift Cranes)

Gauge

Outreach

Hight

Back-reach

Capacity |

35M(8 lanes under span)

68M(23Rows)

43M

18M

Tandem Mode

- Twin 40’/45’ spreader:80T

- Twin cargo bean : 100T

Single Mode

-With Spreader:61T

-Without Spreader: 70T |

Dual-Hoist Quayside Gantry Crane

Dual-Hoist Quayside Gantry Crane

- Enhance productivity to ensure high quality service

- Reduce the berthing time to avoid speeding up on the sea.

1. Average berthing time sabing : 5.7hrs

2. Total Oil consumption saving per voyage: 95.38Tons

( data from 2011 Jan. to Feb.)

Green Terminal

Solar Power System / Administration Building

Solar Power System / Administration Building

- Solar power collection

- Generating 37.7wWp per year

Solar Power System / Gate House

Solar Power System / Gate House

- Generating 90.48kWp per year

- Reduce carbon dioxide emissions108,120 kg per year ( Admin. Building + Gate)

Alternative Maritime Power

Alternative Maritime Power

- Shore-to-ship power, will be install in the Q4, 2011

- Reduce carbon dioxide emissions 470,000 kg per year ( only YM vessels )

Wind Power Generation

Wind Power Generation

- Complex solar and wind power lights set in administrative zone.

- Reduce carbon dioxide emissions 4,388 kg per year ( only YM vessels )

Electric Shuttle Bus

Electric Shuttle Bus

- Two 3-seats, Two 6-seats and Two 14-seats electric shuttle buses.

- Reduce carbon dioxide emissions.

Terminal Landscaping

Terminal Landscaping

- Landscape the Container Yard and Gate area with native plant species of Hong Mao Gan

- Create the sustainable environment.

Green Building

Green Building

- KMCT Admin. Building is the Green Building.

- Office design and constructed with the Eco-technology.

- Match six indicators of Green Building.

- KMCT is the first Container Terminal get the "Green Building" certification in Taiwan.

Material Recycling

Material Recycling

- Container Yard and Quay side filled with the destruction waste of Hong Mao Gan village.

- Create the sustainable environment.

You can link to

KMCT website to have more detail about our Green Terminal

Home

About Us

Environment Protection

Green Vessel